QUALITY PROCESS

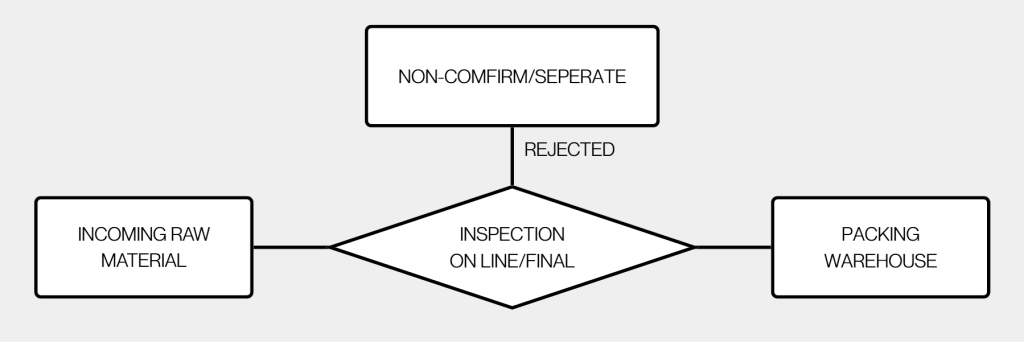

Product control: IQC (Incoming Quality Control) IPQC (In-Process Quality Control) FQC (Final Quality Control) OQC (Out-going Quality Control).

Test standard

| Testing item | Standard Test | Requirements | Confirmation | ||||||

| 1 | Fiber content | AATCC 20/AATCC 20A ASTM D276/D629 REGULATION (EU)NO 1007/2011; ANNEX VIII | SINGLE FIBER: NO TOLERANCE BLENDS OF FIBERS: +/- 3% | – | |||||

| 2 | Weight check (gsm or yd) | ASTM D 3776 | -5.0%/+ 10% ASCLAIMED | ±5 | |||||

| 3 | Light Box | ISO 105-B02:2014 (Method 2 – 20 hours; Xenon light (Blue Wool Scale) | White & Light Shades: ≥ 3-4 Medium & Dark Shades: ≥ 4 Bright & Fluoro Colours: ≥ 2-3 |

||||||

| 4 | Cross staining | GB | – | ||||||

| 5 | Washing Shrinkage | GB/T 8629 | – | ||||||

| 6 | Washing Shrinkage | GB/T 8629-2000 | – | ||||||

| 7 | PH levelPH | GB 7573 | 4.5 – 7.0 | 4.5 – 7.0 | |||||

| 8 | Formaldehyde | ISO 14184-1 | 75PPM MAX | 75PPM MAX | |||||

| 9 | Phenolic yellowing | James H. Heal CS15 (ISO 105:X18:2007 Modified) | ≥ 4.0 (white and Light Shades) |

≥ 4.0 | |||||

| 10 | Color fastness to light | GB/T 8427-2019 | White & Light Shades: ≥ 3-4 Medium & Dark Shades: ≥ 4 Bright & Fluoro Colours: ≥ 2-3 |

>=3-4 | |||||

| 11 | Colorfastness to rubbing(Dry) | CB/T 3920-1997 | All Fabrics: ≥ 4.0 | ≥ 4.0 | |||||

| 12 | Colorfastness to rubbing(Wet) | GB/T 8629 | All Fabrics: ≥ 3.0 | ≥ 43.0 | |||||

| 13 | Colorfastness to Washing |

GB/T3921.1-2008 | 4 | 4 | |||||

| 14 | Colorfastness to Water |

GB/T 5713-1997 | 4 | 4 | |||||

| 15 | Color fastness to Alkali Perspiration |

GB/T 3922-1995 | 3.5 | 3.5 | |||||

| 16 | Colorfastness to Acid Perspiration |

GB/T 3922-1995 | 4 | 4 | |||||

| 17 | Color fastness to water | CB/T 8433 | AATCC 107 | 3.5-4.0 | |||||

| 18 | Apperance after home lundering | GB/T 8629 COLOR CHANGE |

WITHOUT SUPPRESSOR: 3.5 WITH SUPPRESSOR:4.0 | 3.5-4.0 | |||||

| 19. | Dimenional change after home lundering | AATCC 135/150 3 CYCLES PER CARE INSTRUCTION OR AATCC/ASTM TS-006 1 CYCLE |

MAXIMUM % LENGTH & WIDTH – SHRINKAGE / + GROWTH JERSEY/INTERLOCK: -6% / +3% PIQUE/JACQUARDS/FLEECE/ FRENCH TERRY/RIB -7%/-3% THERMAL/FANCY KNITS/BONDEDFABRICS: 8%/ +3% WOVEN -3% / +3% |

-6% / +3% | |||||

| 20 | Pilling Resistance | GB/T 8629 | ISO 12945 -1 (5hr) | Before Wash: 4; After Wash: 3-4 | |||||

WORKFLOW

01

DESIGN

We can submit our own design to you or we can produce one based on your given design. We have established and integrated an R&D team to provide innovative and creative products for our customers successfully.

02

MATERIAL INCOMING

Based on the customer’s request, we offer you various materials from basic quality like cotton/spandex or polyester/spandex and others Cordura more eco-friendly

03

PRODUCTION

Production line is conducted in our own factory under our strict quality control, inspection, analysis, improvement and non-conforming product control: IQC (Incoming Quality Control) IPQC (In-Process Quality Control) FQC (Final Quality Control) OQC (Out-going Quality Control).

04

DELIVERY

Reasonable price and Fast Delivery door to door. Lead time for sample delivery is 7-10 days after swatch color . Lead time for bulk orders is 1,2 week to 1 month depending on the complexity of the customer’s requirements

SHIPMENTS POLICY/ACCOUNT

BANK ACCOUNT:

ACCOUNTEE : BREAK INTO MANUFACTURING CO., LTD

SHIPMENT POLICY:

30% deposit upon order placement, 70% balance upon receipt of Bill of Lading

MCQ/MOQ: 1000M/3000M (400KGS/2000KGS)

QUALITY POLICY:

Defects should be notified to us within 30 days from the date of ETA

LEADTIME

| Titile | Working days | Remark | Q’ty |

| 1.Labdip submission | 7 | *from the date of receiving swatch (but not send later than 7days from the date of confirmed PO date) |

1ea*size A4*A4 |

| 2.Bulk Submision Ex mill (ss) | 35 | *from the date of cf labdip | 1-2y |

| 3.Bulk Submision Approval | 10 | 3 days sending + confirming max 7days | |

| 4.Packing leadtime | 8 | ||

| Total of shipment | 60 | 1.2.3.4 | |

| 5.incase of Re-confirm ( Bulk submission) | 20 | not included customer’s internal testing date | |

| 6.Bulk Submision Approval | 10 | 3 days sending + confirming max 7days | |

| Total of shipment (case of rejection) | 90 | 1.2.3.4.5.6 | |

| Remark: confirming bulk /submission only max 7days, later than this the shipment date will be added accordingly | |||

ABOUT US

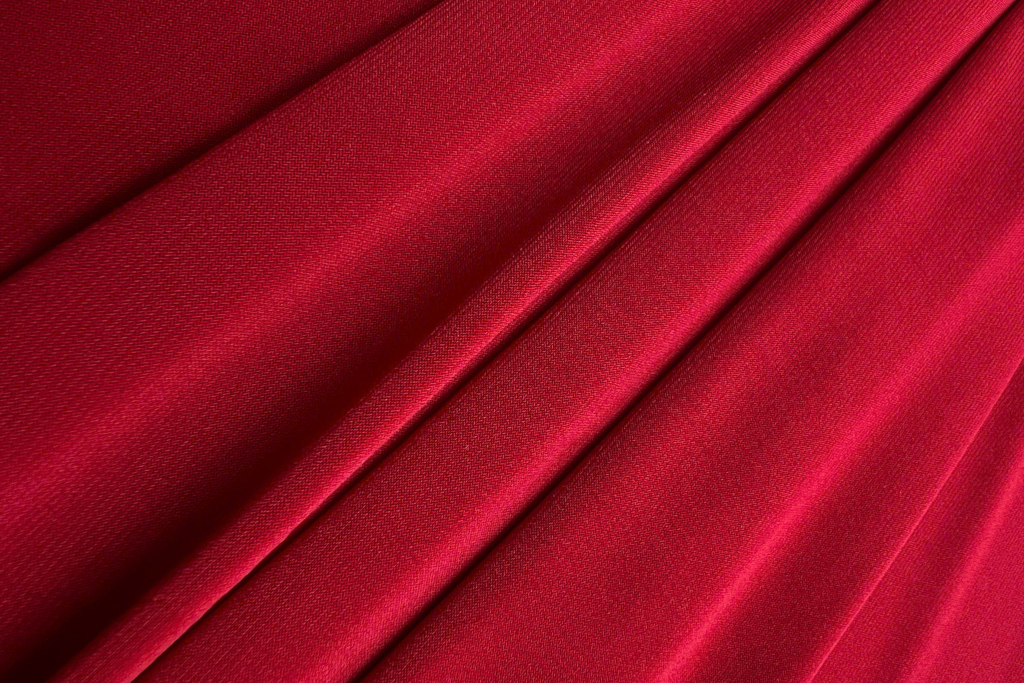

Break Into is a knitting factory specializing in textile production, and dyeing finishing. Our fabrics are used in advanced technologies technical solutions,including: UV protection, wrinkle resistance, anti-static, antibacterial treatment, and others. As a subsidiary, Break Into focuses on the research and development of innovative textile products and is fully licensed for export operations, in compliance with Vietnam’s tax and customs regulations. The quality system at Break Into is built upon strict control procedures, including: PIQC (Process Input Quality Control), OQC (On-line Quality Control), and FIQC (Final Inspection Quality Control).

KNTTING FACTORY

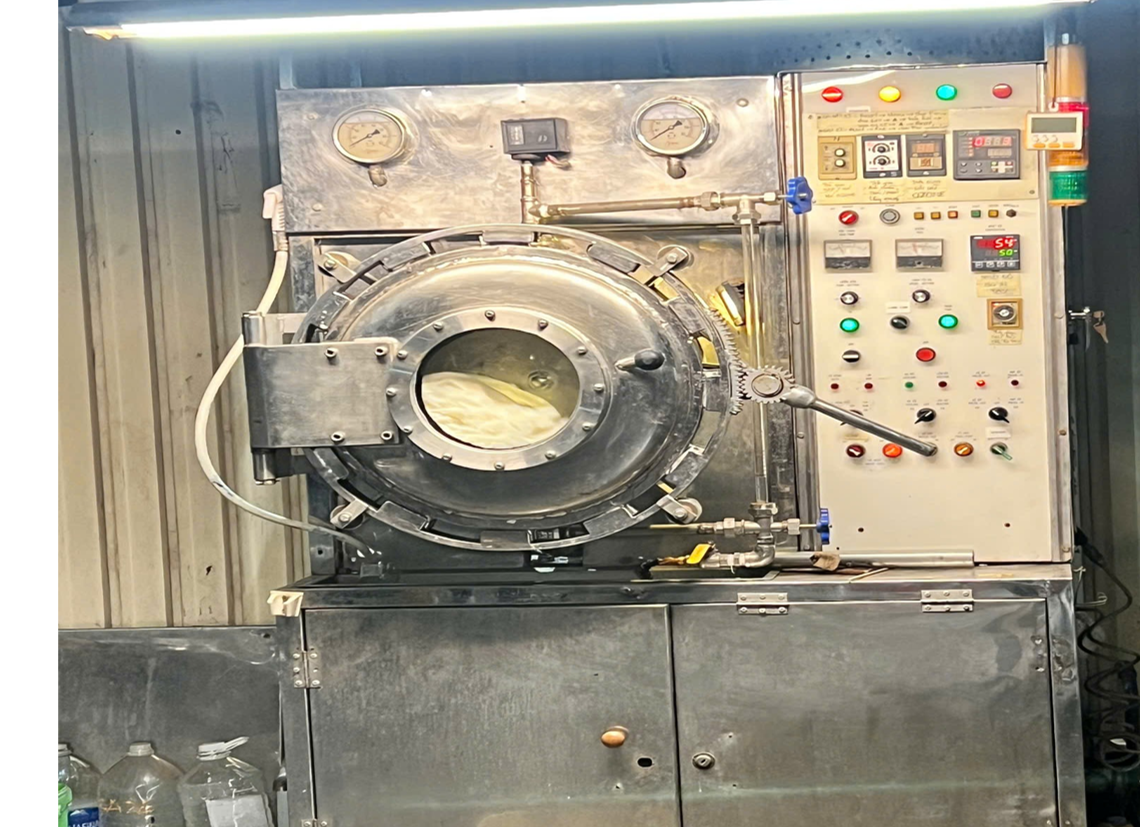

DEYING MACHINE

DEYING MACHINE

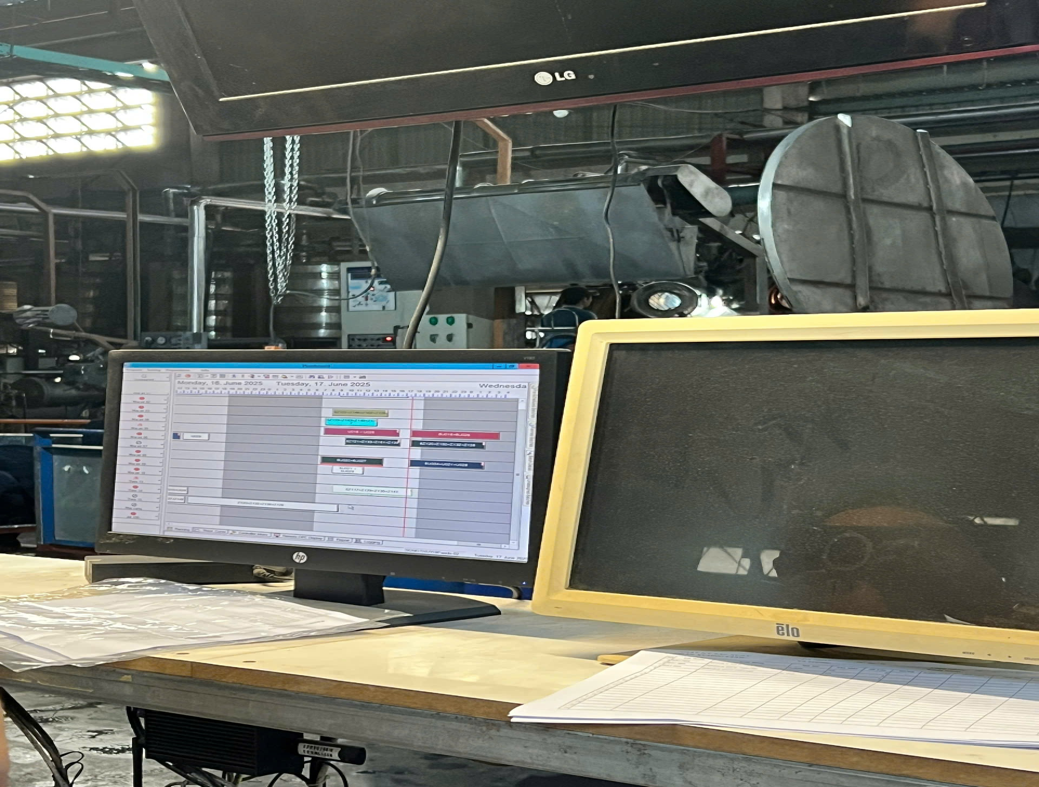

Data input working process

Testing m/c

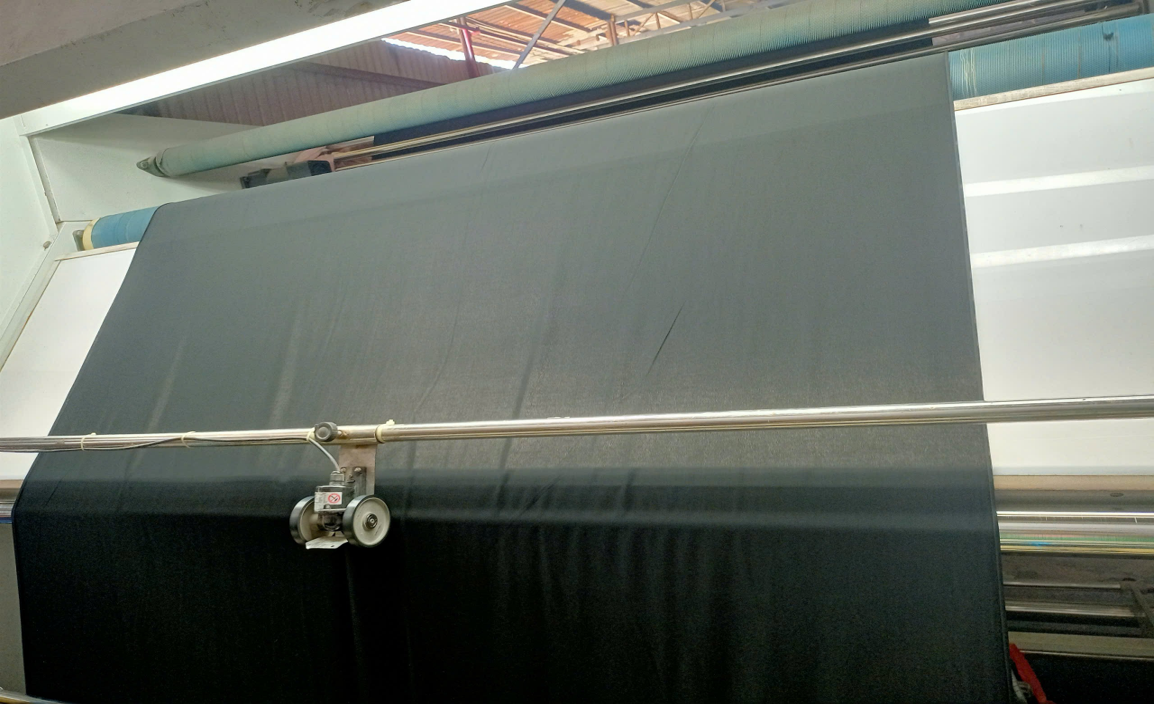

QC inspection

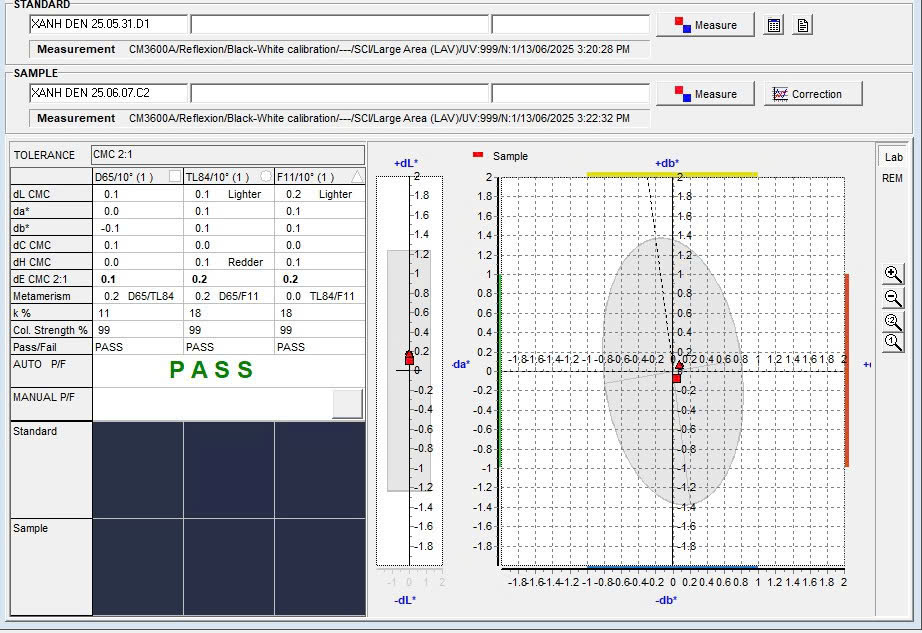

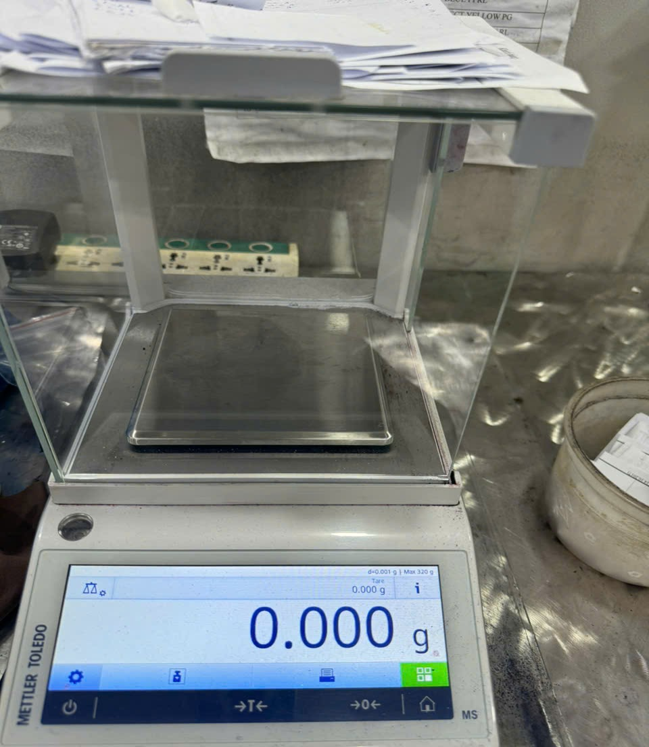

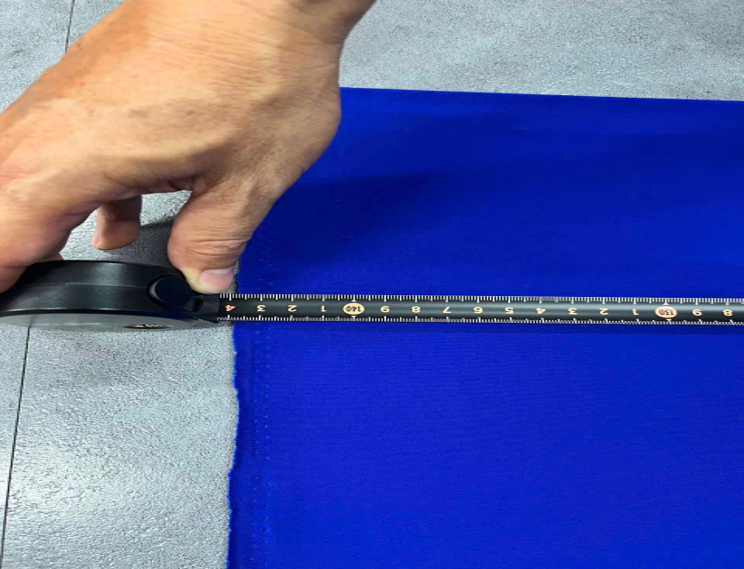

LABROOM

lab test machine

Light box check

WEIGHT check

WIDTH check