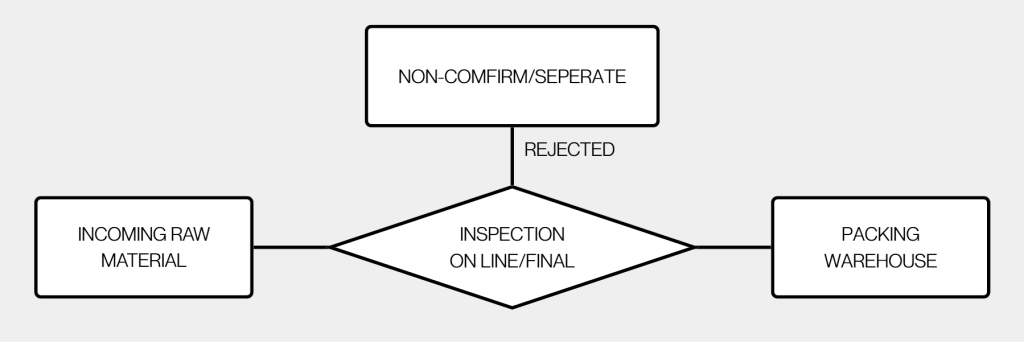

QUALITY CONTROL PROCESS

Product control: IQC (Incoming Quality Control) IPQC (In-Process Quality Control) FQC (Final Quality Control) OQC (Out-going Quality Control).

INTERNAL TEST

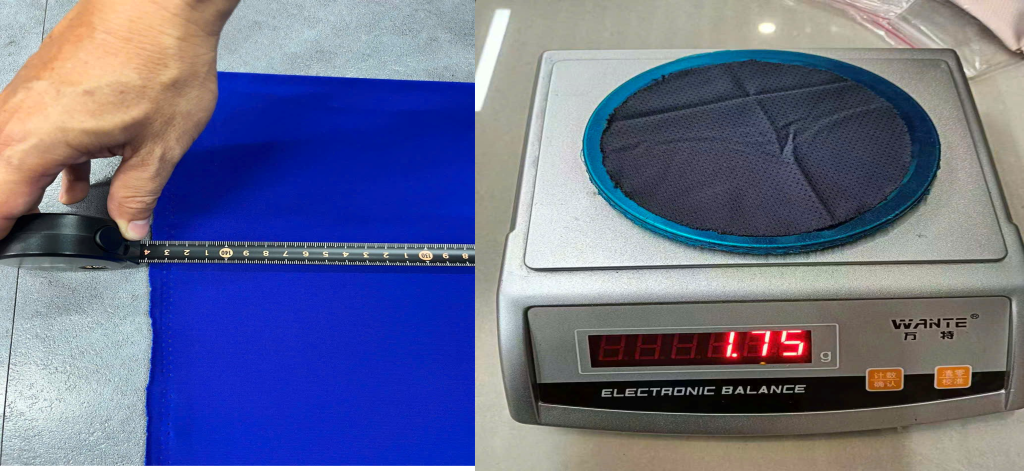

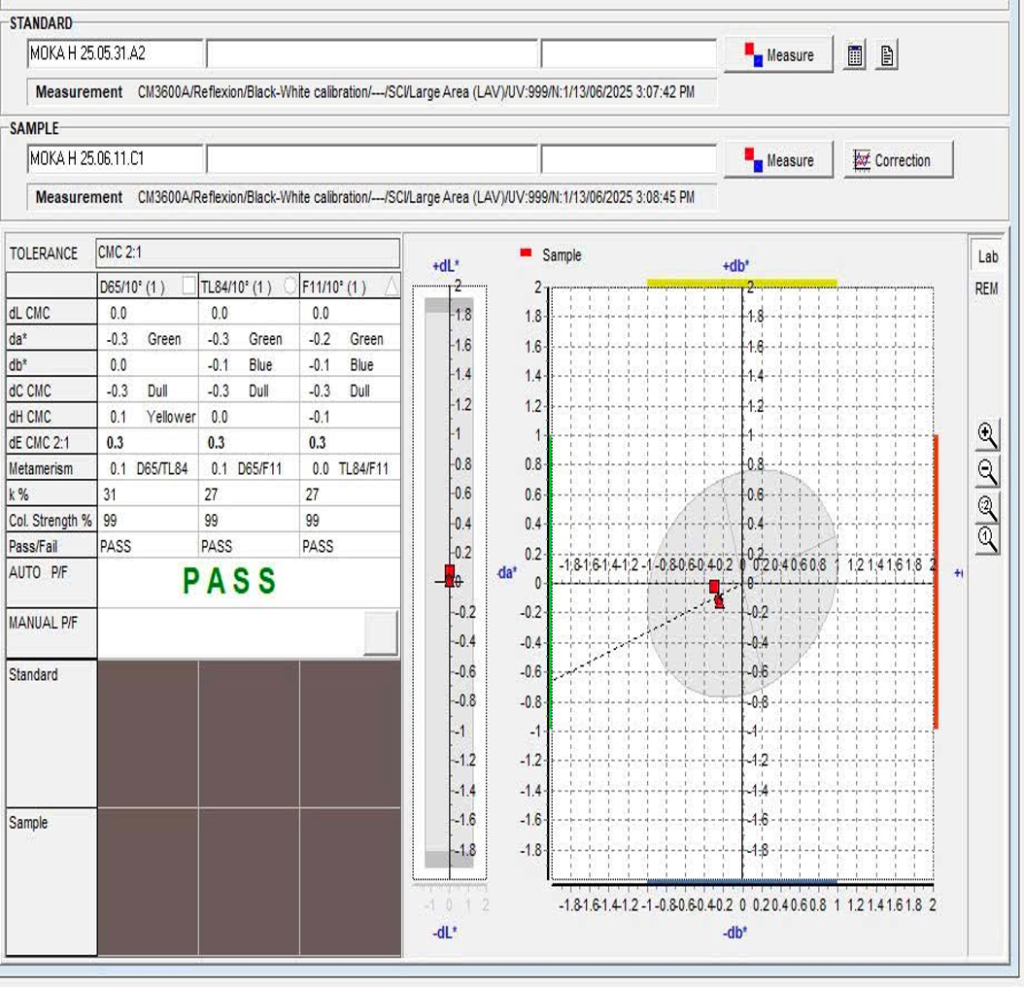

GSM; COLOR FASTNESS; COLOR APPERANCE

( QC check colour fastness; color apperance under light box)

Test standard

| Testinxag item | Standard Test | Requirements | Confirmation | ||||||

| 1 | Fiber content | AATCC 20/AATCC 20A ASTM D276/D629 REGULATION (EU)NO 1007/2011; ANNEX VIII | SINGLE FIBER: NO TOLERANCE BLENDS OF FIBERS: +/- 3% | – | |||||

| 2 | Weight check (gsm or yd) | ASTM D 3776 | -5.0%/+ 10% ASCLAIMED | ±5 | |||||

| 3 | Light Box | ISO 105-B02:2014 (Method 2 – 20 hours; Xenon light (Blue Wool Scale) | White & Light Shades: ≥ 3-4 Medium & Dark Shades: ≥ 4 Bright & Fluoro Colours: ≥ 2-3 |

||||||

| 4 | Cross staining | GB | – | ||||||

| 5 | Washing Shrinkage | GB/T 8629 | – | ||||||

| 6 | Washing Shrinkage | GB/T 8629-2000 | – | ||||||

| 7 | PH levelPH | GB 7573 | 4.5 – 7.0 | 4.5 – 7.0 | |||||

| 8 | Formaldehyde | ISO 14184-1 | 75PPM MAX | 75PPM MAX | |||||

| 9 | Phenolic yellowing | James H. Heal CS15 (ISO 105:X18:2007 Modified) | ≥ 4.0 (white and Light Shades) |

≥ 4.0 | |||||

| 10 | Color fastness to light | GB/T 8427-2019 | White & Light Shades: ≥ 3-4 Medium & Dark Shades: ≥ 4 Bright & Fluoro Colours: ≥ 2-3 |

>=3-4 | |||||

| 11 | Colorfastness to rubbing(Dry) | CB/T 3920-1997 | All Fabrics: ≥ 4.0 | ≥ 4.0 | |||||

| 12 | Colorfastness to rubbing(Wet) | GB/T 8629 | All Fabrics: ≥ 3.0 | ≥ 43.0 | |||||

| 13 | Colorfastness to Washing |

GB/T3921.1-2008 | 4 | 4 | |||||

| 14 | Colorfastness to Water |

GB/T 5713-1997 | 4 | 4 | |||||

| 15 | Color fastness to Alkali Perspiration |

GB/T 3922-1995 | 3.5 | 3.5 | |||||

| 16 | Colorfastness to Acid Perspiration |

GB/T 3922-1995 | 4 | 4 | |||||

| 17 | Color fastness to water | CB/T 8433 | AATCC 107 | 3.5-4.0 | |||||

| 18 | Apperance after home lundering | GB/T 8629 COLOR CHANGE |

WITHOUT SUPPRESSOR: 3.5 WITH SUPPRESSOR:4.0 | 3.5-4.0 | |||||

| 19 | Dimenional change after home lundering | AATCC 135/150 3 CYCLES PER CARE INSTRUCTION OR AATCC/ASTM TS-006 1 CYCLE |

MAXIMUM % LENGTH & WIDTH – SHRINKAGE / + GROWTH JERSEY/INTERLOCK: -6% / +3% PIQUE/JACQUARDS/FLEECE/ FRENCH TERRY/RIB -7%/-3% THERMAL/FANCY KNITS/BONDEDFABRICS: 8%/ +3% WOVEN -3% / +3% |

-6% / +3% | |||||

| 20 | Pilling Resistance | GB/T 8629 | ISO 12945 -1 (5hr) | Before Wash: 4; After Wash: 3-4 | |||||